High-Performance Burst Pressure Test for Airbag Inflators

Precision Under Pressure – Testing Safety at 4,000 Bar

In the world of automotive safety, airbag inflators are mission-critical components. They must perform reliably in a fraction of a second. Every time. To ensure that performance, manufacturers rely on high-precision burst pressure testing to validate airbag inflator integrity under extreme conditions.

At Poppe + Potthoff Maschinenbau GmbH, we specialize in developing advanced pressure testing systems tailored to these exact needs. One such burst test rig involves a 4,000 bar burst test bench, designed for both static and dynamic pressure tests of airbag inflators with maximum accuracy and repeatability.

Customer Challenge: Test Flexibility with Maximum Safety

The requirements are clear: A high-pressure test rig that could not only simulate static burst conditions but also handle highly dynamic pressure surges, simulating real-world failure modes under milliseconds.

The test bench needed to:

- Handle varied inflator geometries

- Offer rapid changeover between test configurations

- Deliver high-speed pressure ramps

- Integrate seamlessly into a production setting

Our Solution: A Robust Dynamic Burst Test Rig

Since shipping the first test rig in 2013, we have continuously improved and delivered many custom solutions comprising:

Burst Test Pressure up to 4,000 bar

Driven by a pneumatically actuated high-pressure pump, pressure is dynamically built up through a dedicated reservoir and released in a controlled burst, achieving test conditions within milliseconds.

Static & Dynamic Test Modes

Operators can switch between test modes via the touchscreen interface. Dynamic bursts are enabled using high-speed valves and a dampened hydraulic architecture to prevent shock and ensure consistent testing conditions.

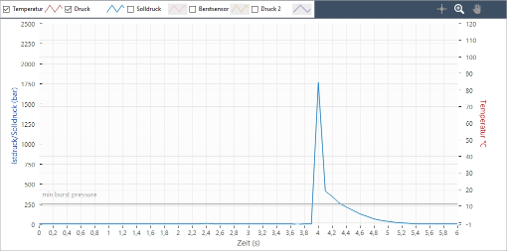

High-Speed Data Capture & LabVIEW Evaluation

Using National Instruments LabVIEW, each burst is tracked with P(t) curves (pressure over time), ensuring detailed insight into burst behavior. Data is logged, stored, and assessed automatically.

Secure Stainless-Steel Test Chamber

A reinforced, fully enclosed test chamber ensures safety, equipped with an observation window and interlocked safety doors that prevent opening during active testing .

Modular Test Fixtures

The bench allows quick changeover between product types using interchangeable connection assemblies. This enables fast adaptation for different test parts—ideal for high-mix, low-volume testing.

Production-Ready Design with Integrated Safety

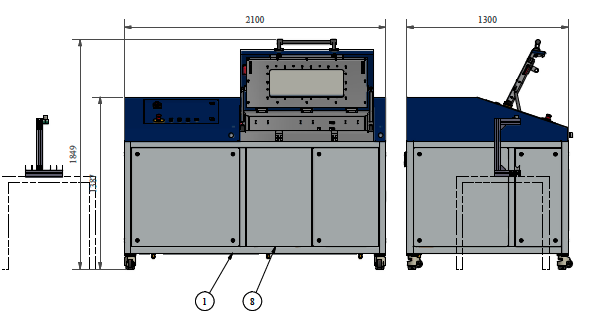

The entire test system is built into a compact dual-module design:

- One half houses the hydraulic system and control cabinet

- The other forms the test chamber

Every component is easily serviceable. Stainless steel tanks, oil mist extraction, leak detection, and emergency shutdown systems are integrated for long-term operation and safety compliance (EN 60204-1).

Outcome: High-Speed, High-Reliability Testing

Our test rig enables reliable, repeatable burst testing in a production environment. The customer can:

- Evaluate inflator performance dynamically

- Log and trace test results

- Adapt quickly to changing product demands

This system plays a crucial role in ensuring airbag safety, by pushing each component beyond its limits, under controlled, repeatable conditions.

Conclusion

At Poppe + Potthoff Maschinenbau, we understand that when it comes to pressure testing safety components, there’s no room for compromise. With over 4 decades of experience and deep technical know-how, we build systems that perform under pressure—so safety-critical parts can too.

If you’re looking to enhance your pressure testing capabilities for inflators, tubes, or safety-critical fluid components, reach out to our team. We’d be glad to support your challenge.