China 7 Emission Standards: Why Pressure Testing & Autofrettage Are More Critical Than Ever

Introduction: The Global Shift Towards Stricter Emission Standards

In recent years, the automotive industry has faced increasing pressure, not just within engines and fuel systems, but from governments worldwide demanding cleaner, more efficient vehicles. At the forefront of this movement are stringent emission standards like Europe’s Euro 6 and China’s adaptation, known as China 7.

For manufacturers and suppliers of high-pressure components, these regulations present both a challenge and an opportunity: A challenge to meet tougher durability and performance requirements, and a chance to lead through innovation and quality assurance.

As specialists in high-pressure testing solutions, we understand how critical this shift is, especially for components like common rails, injector bodies, and high-pressure pumps. This article will explore what China 7 means, which industries and parts are affected, and why advanced testing methods such as Autofrettage and impulse testing are essential to succeeding in this new regulatory landscape.

What Are Euro 6 and China 7 Emission Standards?

Defining Euro 6: The Benchmark for Cleaner Mobility

Introduced in 2014, the Euro 6 standard is a set of regulations aimed at reducing harmful emissions from vehicles, particularly nitrogen oxides (NOx), hydrocarbons, carbon monoxide (CO), and particulate matter (PM). These limits apply primarily to passenger cars and light commercial vehicles, pushing manufacturers to develop cleaner combustion technologies, efficient exhaust after-treatment systems, and optimized fuel injection systems.

China 7: A Stricter Evolution of Euro 6

China, facing severe air quality challenges in its major cities, took decisive action by implementing its version of emission controls—China 7. While heavily inspired by Euro 6, China 7 (introduced in 2020) and the more stringent China 7b phase (mandatory by mid-2023) often exceed European requirements. For example:

- Lower permissible NOx and particulate limits.

- Use of compulsory gasoline particulate filters (GPFs).

- Extended durability requirements for emission control systems.

- Real Driving Emissions (RDE) testing, ensuring compliance beyond laboratory conditions.

China 7 is widely regarded as one of the most demanding emission standards in the world, forcing OEMs and suppliers to innovate rapidly.

Why These Standards Matter

Compliance is not optional. Manufacturers failing to meet China 7 face vehicle bans, fines, and reputational damage. Beyond regulation, these standards drive technological advancements, especially in high-pressure fuel systems designed for cleaner, more efficient combustion.

Industries & Components Affected by China 7

The Automotive Industry Under Pressure

The most immediate impact of the China 7 standards is felt within the automotive industry, from global OEMs to Tier 1 and Tier 2 suppliers. Manufacturers rely on advanced engine designs, optimized combustion, and highly efficient fuel delivery systems to meet these stricter emission limits. At the heart of these improvements lies one key factor: pressure.

Higher fuel pressures enable finer atomization, cleaner combustion, and lower emissions. However, this technological leap places extreme demands on critical components, requiring them to withstand higher operating pressures and longer service life under cyclic loading conditions.

Key Components Affected by High-Pressure Requirements

To comply with China 7, several components must be re-engineered, thoroughly tested, and proven to perform reliably under harsh conditions:

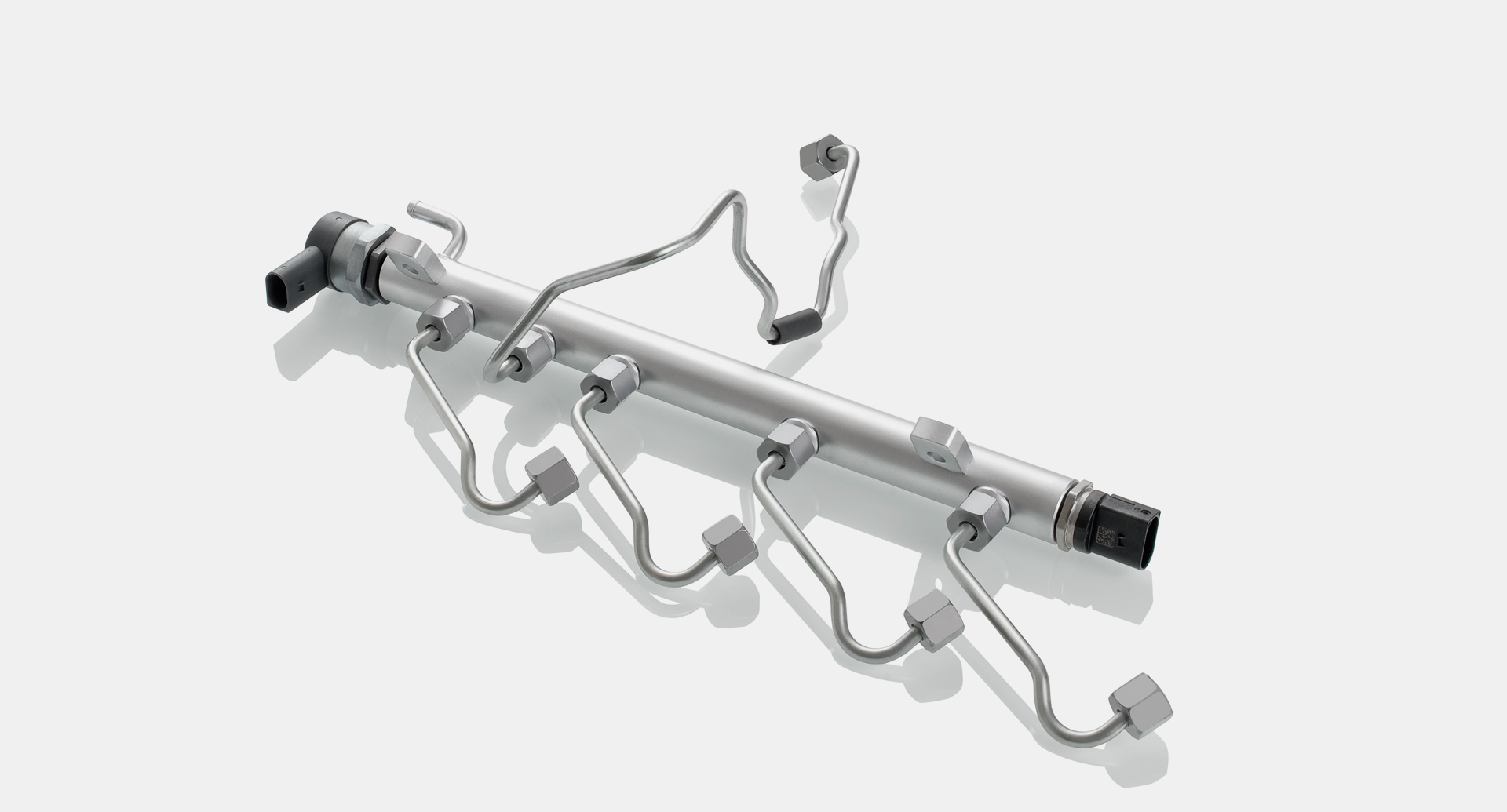

Diesel Fuel Common Rails

Common rails are central to modern diesel and gasoline direct injection systems. They must endure extreme pressures while maintaining precision fuel delivery.

Injector Bodies & Nozzles

Responsible for precise fuel injection timing and pattern, injectors face constant high-pressure cycles.

High-Pressure Pump Heads

These components generate the required fuel pressure, often exceeding 2,500 bar in modern systems.

Fuel Rails and Accumulators

Fuel rails are designed to store and distribute pressurized fuel evenly across injectors and common rails

Other affected components are Hydraulic Lines, Fittings, and connectors that ensure the safe, leak-free transport of high-pressure fluids, Valves and control Units critical for managing pressure regulation and flow control within fuel systems, and Turbocharger Housings.

Each component must pass rigorous testing protocols to handle the operational demands imposed by China 7 regulations.

The Growing Importance of Pressure Testing & Autofrettage

Why Advanced Testing Is Essential for China 7 Compliance

With rising pressure levels and extended durability expectations, traditional testing methods are no longer sufficient. Manufacturers must validate their components through high-pressure impulse testing and enhance material strength via Autofrettage to stay ahead of regulatory demands.

High-Pressure Impulse Testing: Simulating Real-World Stress

Impulse testing subjects components to rapid pressure cycles, replicating the stresses experienced during a vehicle’s lifetime. This process:

- Identifies potential weaknesses such as fatigue cracks or material failures.

- Ensures components meet lifecycle expectations under cyclic loading.

- Validates compliance with industry standards like ISO 19879 and ISO 16922 for hydraulic and fuel system components.

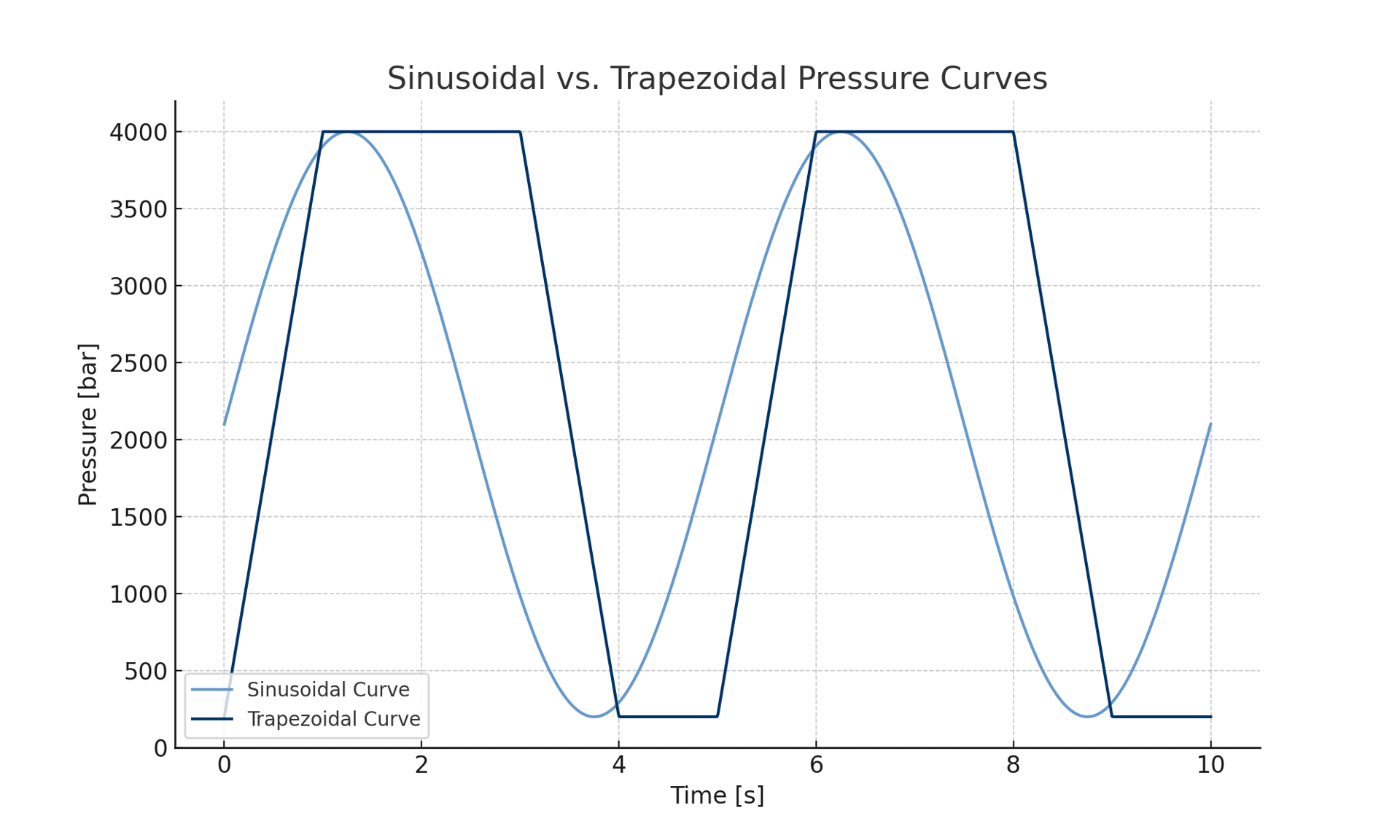

- Exposes components to sinusoidal and or trapezoidal pressure curves

Impulse testing is recommended and critical for components like common rails, injector bodies, and pump heads.

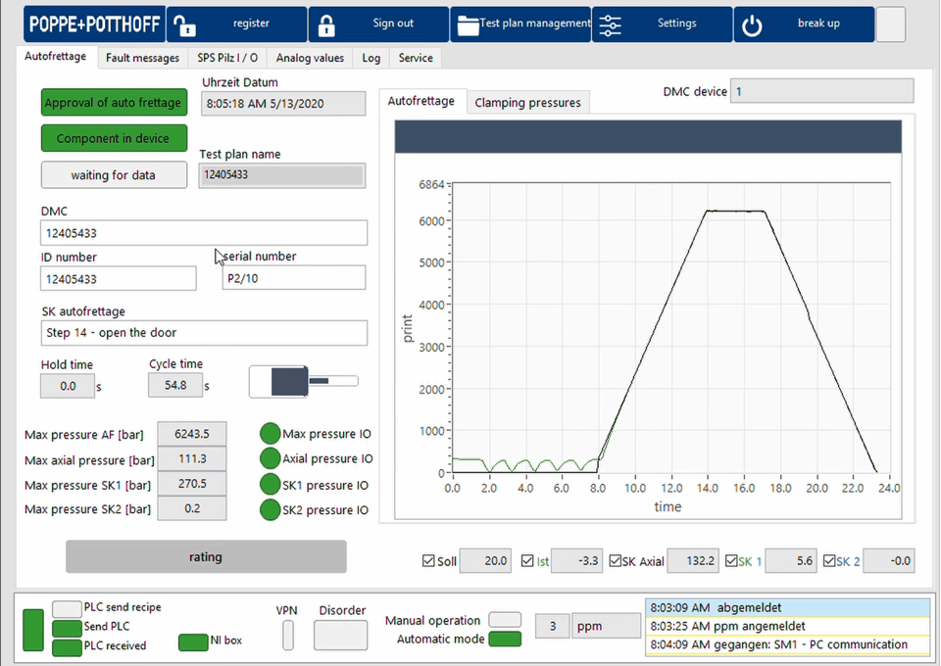

Autofrettage: Strengthening Components from Within

Autofrettage is a process where components are exposed to pressures beyond their elastic limit, inducing beneficial residual stresses. This significantly increases:

- Fatigue life

- Resistance to pressure-induced deformation

- Overall safety margins

Autofrettage is especially valuable for thick-walled pressure vessels and components in high-pressure fuel systems, where durability under China 7 requirements is paramount.

Conclusion: Preparing for China 7—Why the Right Testing Partner Matters

As China 7 sets a new global benchmark for emission standards, the demands on high-pressure components will only continue to grow. Manufacturers who invest in advanced testing solutions today are safeguarding their compliance, reputation, and competitive edge for tomorrow.

At Poppe + Potthoff Maschinenbau GmbH, we deliver customized high-pressure test stands and Autofrettage systems to meet the toughest industry challenges. Our solutions help ensure that your components withstand modern mobility’s regulatory and mechanical pressures.

Ready to future-proof your components?

Contact us to learn more about our tailored testing solutions for China 7 compliance and beyond.

FAQ: China 7, Pressure Testing & Autofrettage

What is the China 7 emission standard?

China 7 is a stringent vehicle emission regulation based on Euro 6, designed to reduce air pollutants such as NOx, particulate matter, and hydrocarbons in China.

How does China 7 impact automotive suppliers?

Suppliers must design and validate components that can withstand higher pressures, longer lifecycles, and stricter performance criteria.

What is Autofrettage in automotive manufacturing?

Autofrettage is a process that strengthens pressure-bearing components by applying high pressure to induce beneficial residual stresses, extending fatigue life.

Why is pressure testing necessary for emission compliance?

Pressure testing ensures components like common rails, injectors, and pumps can handle extreme operating conditions without failure, which is vital for meeting emission standards like China 7.